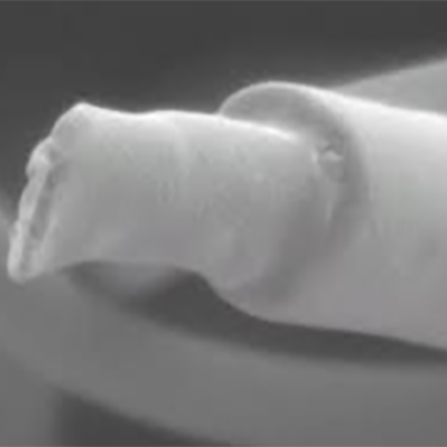

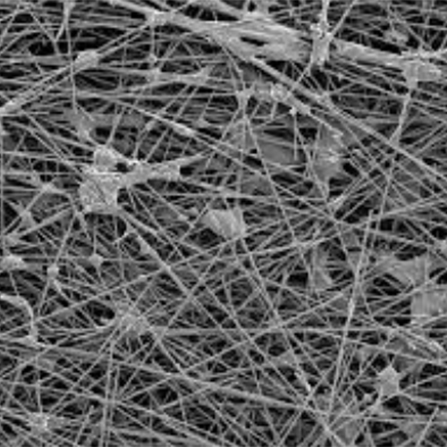

Low Melting Fiber

It is produced by bi-component spinning of general polyester and modified polyester, can be melted at lower temperature (110~200ºC) than normal fiber and bonded with other fibers so it has exceptional adhesive strength. We can also offer fibers for hygiene products which are produced by bicomponent spinning technology with polyethylene (Sheath) and polypropylene (Core), has softer characteristics than normal polyester low melting fibers, and used for multi-functional materials to get hydrophilic or hydrophobic properties and high lofted soft non-woven. Low melting fibers can be used in the hygiene industry, bedding (quilts, mattresses, padding) as well as for car interiors.